Quality and reliability in the field of precision mechanical processing.

Coim Tech s.r.l. started the activity in 1981 in the field of precision CNC machining.

We are mainly present in the sectors energy (turbine blades), automotive, sporting weapons, textile machinery and the fine mechanics in general.

Our fleet includes:

- 3 Ferrari CB 5 and 6-axis vertical machining centers

- 3 Makino horizontal machining centers with 4 and 5 continuous high-speed axes; palletized

- 1 YCM 3-axis machining center with 1630x762x700 mm quay

- 1 YCM 5-axis high-speed continuous machining centre

- 1 Okuma LB15 lathe

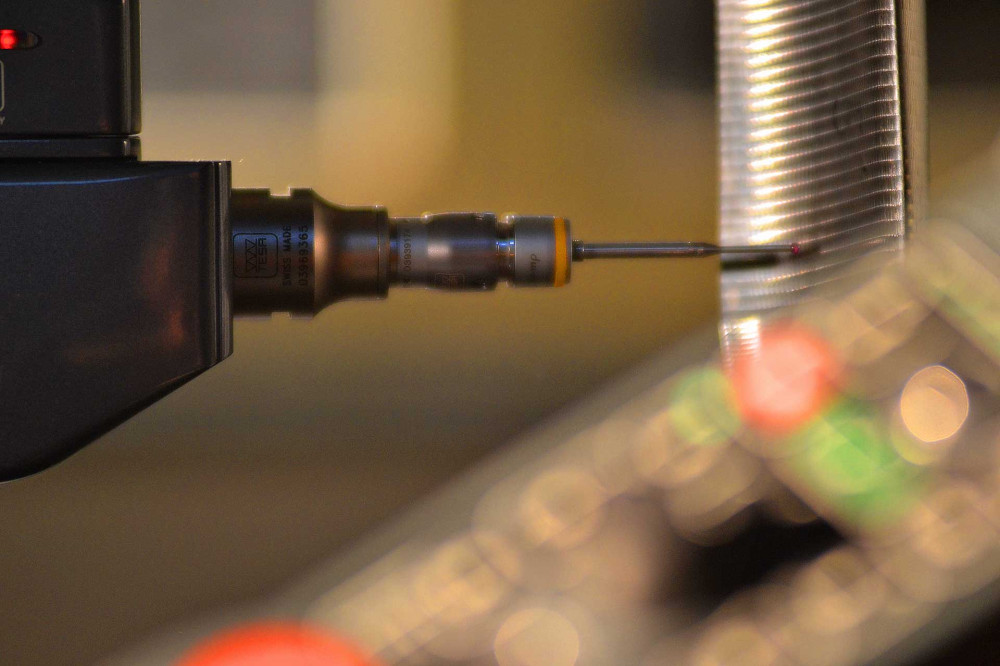

We have a testing room equipped with four three-dimensional measuring machines Tesa-Dea, one manual and three automatic, interfaced with PC-DMIS software for the comparison between the detected piece and the mathematical model, digital altimeters Mitutoyo and Trimos as well as various control instruments for the mechanics.

The CNC programming is made with CAD-CAM systems both 2 axes and a half and 3D and with dedicated programs for 5 axes.

When available we use the customer's mathematical model, otherwise we can create it with our CAD software tools.

In specific cases we can reconstruct the part starting from the sample provided by the customer.

Equipment and special tools are entirely designed by us and built internally.